Purchase points:

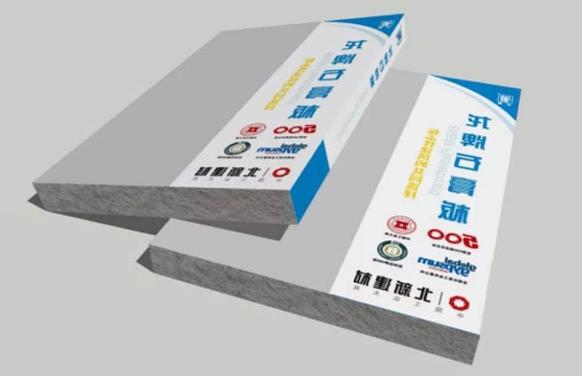

First, ask for quality inspection reports to understand product quality。

The second is to check the appearance quality, carefully check whether the front of the gypsum board has oil stains or watermarks, whether the front of the gypsum board is flat, and whether there are more and deeper corrugated grooves and scratches。

Third, check the degree of adhesion between the veneer paper and the board core。To randomly find a few sheets of plates, exposed at the end of the gypsum core and the protective paper with the hand to uncover the protective paper, if the uncovered place of the protective paper appears interlayer tear, indicating that the protective paper of the sheet and the gypsum core bond well;If there is a tear between the cover paper and the gypsum core layer at the uncovered place, it indicates that the plate is not bonded。

Ingredients:

备料:

Modified starch, retarding agent, pulp, water reducing agent and water are quantitatively measured and mixed into raw material pulp by hydraulic pulper, and then pumped into slurry reserve tank for use.

Pour the blowing agent and water into the blowing agent preparation tank in proportion to stir well, pump into the blowing agent reserve tank (with heating device, keep above 35℃) for use;

The coagulant and gypsum powder raw materials are put into the silo for reserve by lifting and conveying equipment.

配料:

The slurry in the slurry reserve tank is pumped into the mixer using a metering pump, the foaming agent is foamed into the mixer using a dynamic foaming device, the coagulant and gypsum powder are measured into the mixer using a fully automatic metering belt, and then all the main auxiliary materials are mixed into qualified gypsum slurry in the mixer。

说明:

The addition of all main auxiliary materials is included in the automatic control system, which is automatically adjusted with the different speed of the production line to meet the requirements of large-scale and high speed。Introduction: The board core and the veneer paper have been waterproof treatment, according to the requirements of the national standard, the paper surface and the board core of the water-resistant paper gypsum board must meet certain waterproof requirements (the surface water absorption is not more than 160 grams, the water absorption rate is not more than 10%)。Water-resistant paper gypsum board is suitable for use where the continuous relative humidity does not exceed 95%, such as toilets, bathrooms, etc。

Chongqing public network Anbei 50010602502835

Chongqing public network Anbei 50010602502835